1. What are PET Preforms?

- Definition:

Explain that PET preforms are intermediate plastic products, essentially miniature vials, that are blown into finished plastic bottles. - Manufacturing Process:

Describe the injection molding process, including heating the PET resin, injecting it into a mold, and cooling it to create the preform shape. - Key Features:

Highlight the different neck sizes, weights, and shapes of preforms and how they vary based on the final bottle application.

2. Applications of PET Preforms:

- Beverage Industry:

Discuss how PET preforms are widely used for packaging water, soft drinks, juices, and other beverages. - Food Industry:

Explain their use in packaging edible oils, sauces, and other food products. - Cosmetics and Personal Care:

Highlight their role in packaging various cosmetic and personal care items. - Pharmaceuticals:

Detail their use in packaging medications and other healthcare products.

3. Sustainability and PET Preforms:

- Recycling:

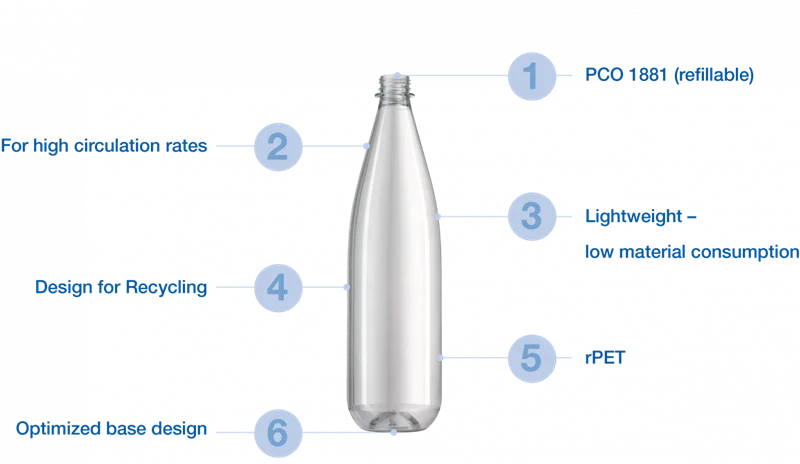

Emphasize the recyclability of PET and how preforms contribute to a circular economy. - rPET Integration:

Explain how recycled PET (rPET) can be incorporated into preform manufacturing, reducing reliance on virgin materials. - Eco-Friendly Packaging:

Discuss the environmental benefits of using PET preforms compared to other packaging materials.

4. Choosing the Right Preform:

- Weight and Size:

Explain how the weight and size of the preform are determined by the final container's capacity and intended use. - Neck Finish:

Discuss the importance of neck finish compatibility with the cap and closure system. - Transparency and Quality:

Highlight the need for high clarity and quality, especially for beverage bottles.

5. PET Preform Testing and Quality Control:

- Perpendicularity Testing:

Explain how preform perpendicularity is tested to ensure the final bottle is correctly aligned. - AA Level Testing:

Discuss the importance of keeping acetaldehyde (AA) levels low in preforms and the use of AA blockers. - Quality Control Processes:

Detail the various quality control measures taken during preform manufacturing to ensure high standards.

6. Trends and Innovations:

- Lightweighting:

Discuss the trend of using lighter preforms to reduce material consumption and transportation costs. - Design Innovations:

Explore how new preform designs are being developed to enhance functionality and aesthetics. - Advanced Manufacturing Techniques:

Highlight the use of modern, high-speed injection machines in preform production.

By covering these topics, a PET preform blog can provide valuable information to a wide audience, including those in the packaging industry, businesses using PET preforms, and consumers interested in sustainable packaging options.